When it comes to crusher parts sourcing, many buyers assume it’s all about the right price. But price alone can be deceptive — especially when you're sourcing from a complex and often opaque supply chain like China’s.

The real edge comes from knowing what to buy where, and how to identify the right type of supplier for each category of crusher parts.

Whether you’re sourcing crusher wear parts like jaw plates and blow bars, or crusher spare parts like shafts, bearings, or housings — the wrong match can result in delays, poor fit, and long-term operational losses.

Let’s break down five smart crusher parts sourcing strategies to help you make the right calls — and avoid expensive traps.

| Crusher Part Type | Ideal Supplier |

|---|---|

| Standard crusher wear parts (jaw plates, mantles, hammers) | Large or mid-sized foundries with casting lines |

| Crusher spares (bearings, bushings, shafts, housings) | Precision machining workshops |

| Customized / legacy crusher parts | Agile factories with reverse engineering capacity |

Large foundries are excellent for high-volume crusher wear parts, but not ideal for small-batch machining. On the other hand, a workshop may be agile enough for one-off custom items — but lack metallurgical expertise for castings.

The key is matching your crusher part type to supplier capabilities, not just comparing unit price.

A common buyer mistake: sending the entire crusher parts RFQ list to a single supplier, hoping for “one-stop sourcing.” The result? Delays, mismatched quality, and bloated pricing — especially when you’re mixing crusher wear parts with machined crusher spare parts.

In reality:

Solution: Segment your crusher parts RFQ based on part type and production complexity. This gives you better control over lead times and lets each supplier focus on what they do best.

Unlike standard crusher wear parts, crusher spares often lack universal codes or references. You might only have a sample, partial drawing, or an old machine number.

If you want to purchase scattered components such as housings, shafts, bearings, adapter plates or other crusher spares

You’ll need a supplier that can:

If you’re dealing specifically with crusher wear parts, check our Crusher Wear Parts Buying Guide for a more in-depth breakdown.

Here’s the hidden problem most crusher parts buyers don’t see:

Many Chinese crusher parts manufacturers have no foreign sales team, no English catalog, and no online presence.

This means most buyers go through trading companies. And that’s fine — unless your trading partner is also buying from another trader.

In this case, you get:

Delayed pricing feedback

Stacked markup

No idea who made your crusher parts

Zero fitment accountability

Smart buyers look for a trade partner who:

Knows which factories specialize in which crusher parts

Can quote factory-direct pricing

Provides technical feedback, not just a number

Maintains a real manufacturer network, not just a contact list

A good sourcing agent is not just a messenger — they’re your factory translator, QA filter, and cost control center.

The more you know your crusher parts, the more control you have.

Sending vague part names or outdated numbers creates room for error — and weakens your position when comparing crusher part suppliers. Instead:

Collect photos + wear measurements

Provide dimensional sketches or samples

Ask suppliers to confirm via drawing or spec sheets

Record which supplier quoted which version

Over time, this builds your internal database of crusher parts, making future purchases faster and more accurate — and reducing your dependence on “guess quotes.”

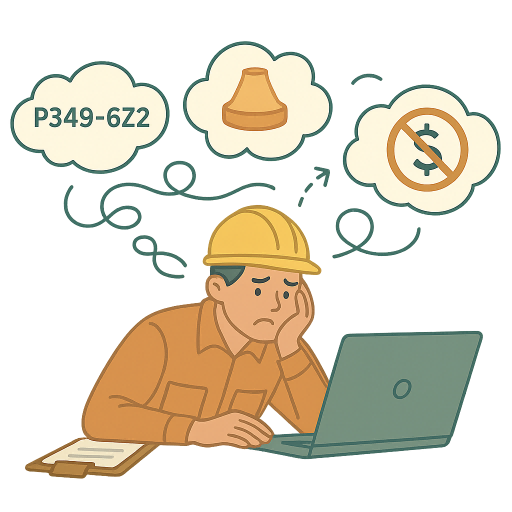

At PAJOA, these strategies aren’t just theory — they’re how we operate every day.

For large structural crusher parts like frames and shafts, we work directly with Shenyang foundries, known for high-grade cast iron and heavy-duty casting expertise.

For precision crusher spares like housings, bushings, and bearings, we source from Jiangsu and Zhejiang, China’s core hubs for brass alloy forging and high-tolerance machining.

For crusher wear parts, we don’t take a one-size-fits-all approach. Instead, we match your working conditions with the right combination of material upgrades — whether it’s TIC inserts, tungsten reinforcement, or proprietary heat treatment profiles.

That’s how we turn crusher parts sourcing strategies into real-world results — and why buyers trust us not just to quote, but to guide.

Crusher parts sourcing is no longer just about finding “the cheapest option.” It’s about knowing the right supplier for each crusher part type, asking the right questions, and working with a trade partner who knows the real crusher parts supply chain landscape — not just who responds fastest on Alibaba.

If you’re tired of markups without answers, quotes without clarity, and delays without explanation — maybe it’s time to upgrade how you source crusher parts.

Want to talk crusher parts sourcing strategy? Let’s connect.