We supply high-performance cone crusher liners — including bowl liners, also called mantlesy concavidades — built to match your machine and working conditions. From standard replacements to custom chamber profiles and material. PAJOA helps you find the cone wear parts that fit and last.

En PAJOA, we go beyond basic supply. We help you find the crusher cone liners that actually perform under your site's conditions.

Whether you need just the manto, the concave, or the full wear set, we deliver matched solutions — based not only on your crusher model but on your working material, feed sizey chamber pressure.

Matching chamber profiles is not guesswork. Whether you're working with a Symons short head, a Metso HP300 Coarse, or a Sandvik CH440 Medium, we can replicate the original geometry down to the detail — or fine-tune it for your current throughput needs.

We know which Chinese foundries specialize in which alloys and profiles, helping you avoid guesswork. And we’re ready to supply liners that don’t just fit — they outperform. Know more about outstanding partners in China.

Most cone crusher liners start with manganese steel: Mn13Cr2 or Mn18Cr2. For tougher jobs, Mn22Cr2 or TIC-insert liners bring extra strength. In silica-heavy or abrasive stone, our ceramic-reinforced options help extend liner life and reduce changeouts.

Each liner — whether bowl liner, manto, or concave — can be cast up to 14 toneladas, supporting even the largest crushing operations.

And based on real-world feedback, our reinforced mantles and concaves have reached up to 1.5× the wear life of previously used parts.

Consolidamos los mejores recursos de piezas de trituradoras de China para ofrecer los productos más adecuados y de mayor calidad para su equipo.

Con almacenes en toda China, ofrecemos acceso rápido al recambio de trituradora que necesita, cuando lo necesita.

Nos especializamos en la producción de piezas de calidad OEM idénticas a las originales, con el mismo aspecto, acabado y rendimiento.

Nuestra fabricación cumple las normas ISO, las normas nacionales chinas, ASTM (EE.UU.), EN (Europa) y JIS (Japón).

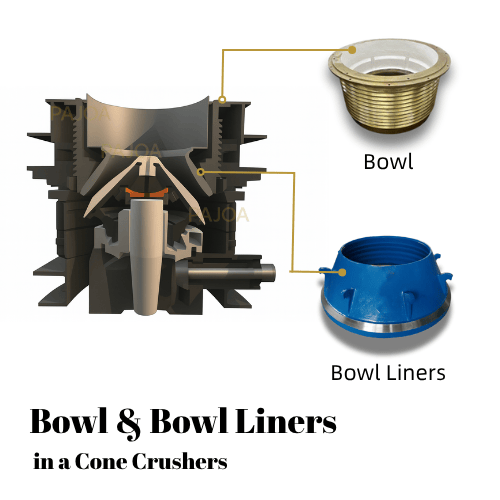

En bol is the fixed outer shell of the cone crusher — it doesn’t wear out and isn’t replaced.

En bowl liner, however, is the replaceable wear part mounted inside the bowl that works with the mantle to crush material.

Looking for the actual cone crusher bowl structure instead?

👉 Click here to learn more about the cone crusher bowl

You can fill out the contact form at the bottom of the page or message us directly via WhatsApp.

To speed up the process, provide your part number, crusher brand/model, and the specific parts you're looking for — whether it's a manto, concave, or a full cone crusher liner set.

No, we are not the OEM.

But we provide 1:1 interchangeable replacements for brands like Metso®, Sandvik®, Symons®, Trio®, Terex®, and more — with the option to improve the alloy formulation or wear resistance based on your needs.

There’s no fixed MOQ. Whether you need a single mantle or a container load of cone crusher liners, we welcome your inquiry.

We’re here to help — no matter the order size.

Good question — and one we hear often.

To avoid mismatches, delays, or poor-quality castings, we recommend reading our full Guía de compra de piezas de desgaste para trituradoras →

It breaks down what matters: part fit, material quality, supplier reliability, and how to identify real value behind price.