When it comes to crusher parts sourcing, many buyers assume it’s all about the right price. But price alone can be deceptive — especially when you're sourcing from a complex and often opaque supply chain like China’s.

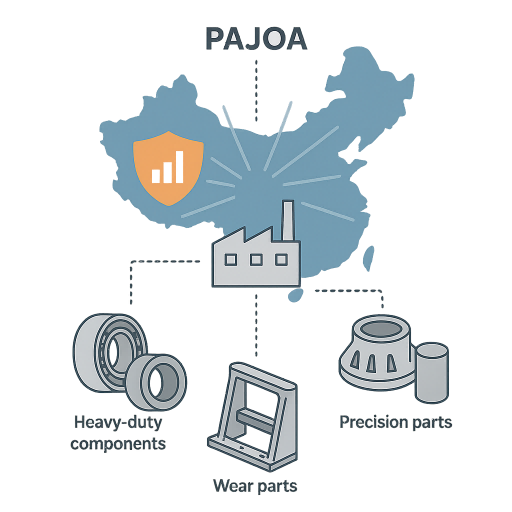

The real edge comes from knowing what to buy where, and how to identify the right type of supplier for each category of crusher parts.

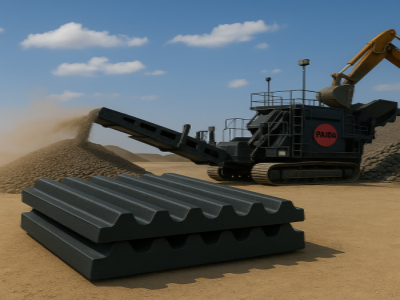

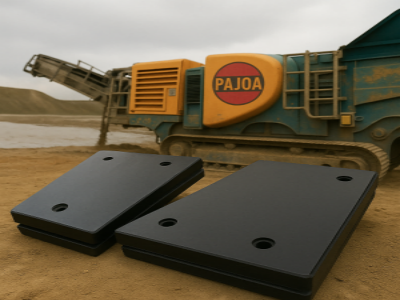

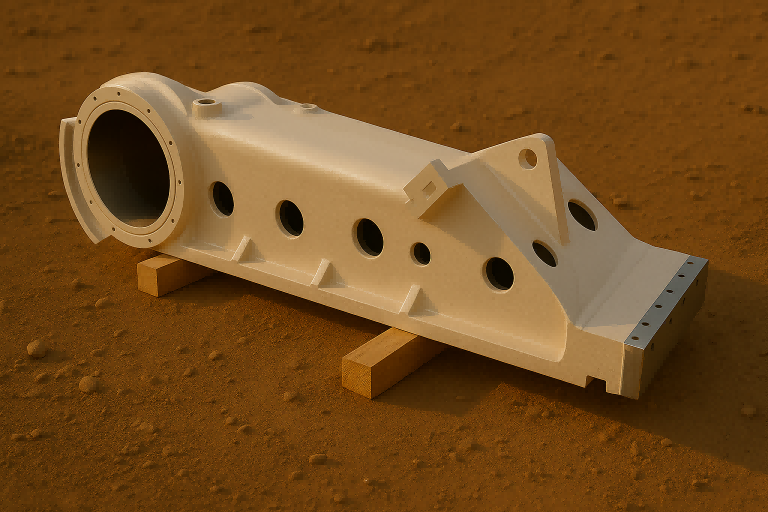

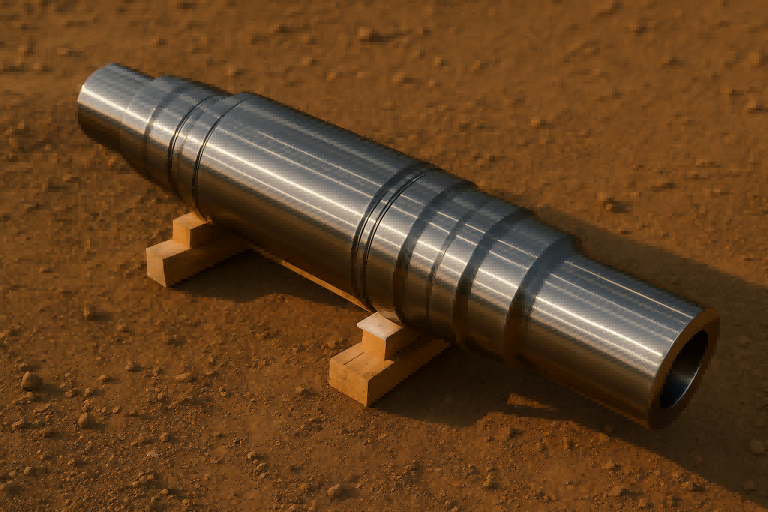

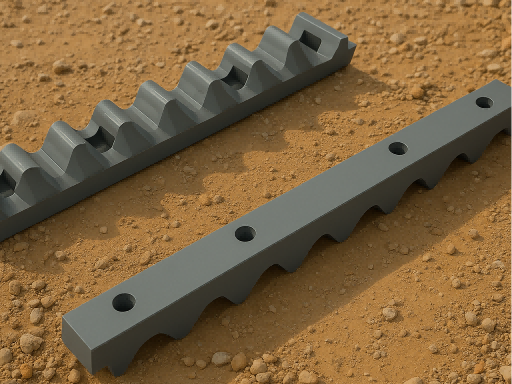

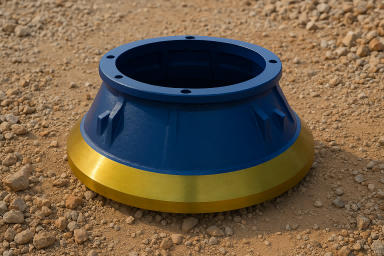

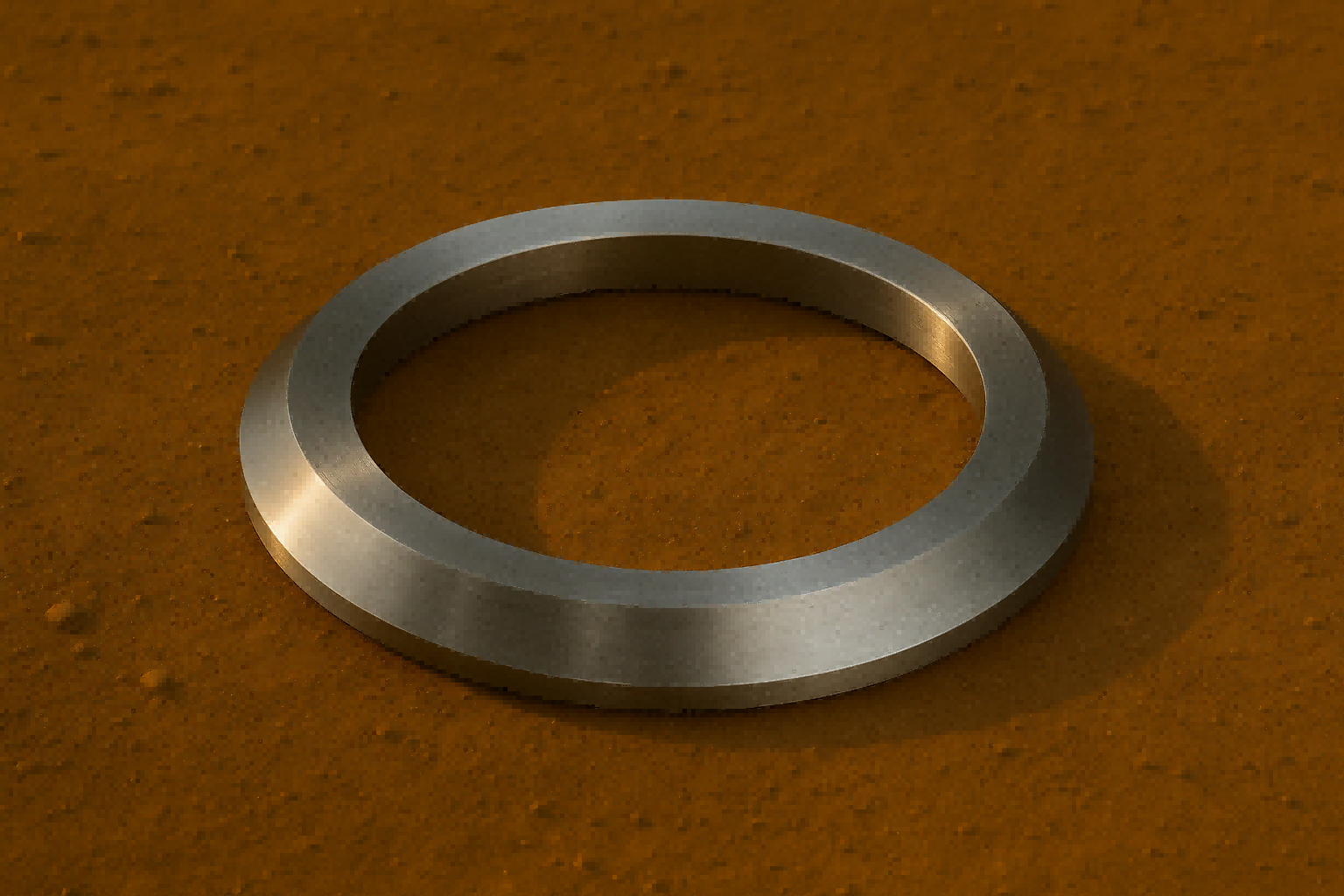

Whether you’re sourcing crusher wear parts like jaw plates and blow bars, or crusher spare parts like shafts, bearings, or housings — the wrong match can result in delays, poor fit, and long-term operational losses.

Let’s break down five smart crusher parts sourcing strategies to help you make the right calls — and avoid expensive traps.