The HS Series multi-cylinder hydraulic cone crushers are engineered for high-capacity secondary and fine crushing. Featuring advanced automation, optimized chamber design, and reliable performance, they deliver superior particle shape, consistent output, and efficient operation across mining, quarrying, and aggregate production applications.

Higher Productivity

The HS series vertical shaft impact crusher is designed to meet the demands of high output and fine crushing. It adopts deep-cavity rotor technology and optimized crushing chamber design, significantly improving crushing efficiency and output capacity. Especially suitable for large-scale sand production lines, the HS series significantly outperforms conventional impact crushers in terms of throughput and final product quality.

Superior Quality

Thanks to its advanced design, the HS series ensures consistent and excellent product grain shape. The machine's crushing chamber and rotor design help eliminate flaky and elongated particles, delivering uniform cubical end products. This not only improves the quality of finished aggregates but also enhances performance in downstream applications such as concrete and asphalt.

Excellent Grain Shape

The machine adopts a rock-on-rock or rock-on-steel crushing principle to ensure a well-graded, uniformly sized product. The fine particle shape makes it particularly suitable for applications with strict requirements on final product grading, such as high-performance concrete and highway construction.

Shorter Maintenance Time and Downtime

The modular design of the HS series allows quick access to core components and replacement of wear parts. Combined with centralized lubrication and hydraulic opening mechanisms, the crusher minimizes downtime and simplifies maintenance. Wear-resistant materials are used in all key components to extend service life.

Versatile Applications

With adjustable rotor speed, chamber configuration, and feed size, the HS series can flexibly adapt to a wide range of production requirements and materials. It’s suitable for crushing various hard and abrasive rocks, making it ideal for both fine and coarse applications.

Ease of Maintenance

The HS series features easy-to-replace wear parts, including the anvils, rotor tips, and liners. These parts are made from high-strength wear-resistant materials and designed for quick change-out using standard tools, minimizing labor intensity and downtime. The hydraulic lifting device further simplifies maintenance and reduces labor costs.

Low Maintenance Cost

All wear parts adopt modular design and use high-quality, high-wear-resistant materials, reducing replacement frequency and spare parts cost. The integrated lubrication system and advanced protection mechanisms ensure stable long-term operation while keeping the maintenance burden low.

User-Friendly Operation

With automatic start-stop, centralized control, and intelligent fault diagnosis, the HS series crusher is easy to operate and integrate into automated production lines. The DCS system can be connected for remote monitoring, achieving intelligent and safe control.

| Модель | Unit | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 45mm | 51mm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HS200 | t/h | 90–120 | 120–150 | 140–180 | 150–190 | 180–210 | 200–250 | 230–300 | 250–310 | 280–350 | 300–400 |

| HS300 | 105–140 | 135–180 | 150–200 | 180–220 | 210–250 | 230–280 | 260–320 | 280–340 | 310–390 | 350–440 | |

| HS400 | 115–150 | 150–185 | 170–220 | 200–240 | 230–280 | 250–300 | 280–340 | 300–360 | 330–420 | 370–460 | |

| HS500 | 135–170 | 160–200 | 185–230 | 215–260 | 240–290 | 270–320 | 300–360 | 320–380 | 350–440 | 390–480 | |

| HS600 | 175–220 | 230–280 | 250–300 | 270–320 | 300–350 | 320–370 | 340–400 | 370–430 | 400–470 | 430–500 | |

| HS700 | 195–240 | 250–300 | 270–320 | 300–350 | 330–380 | 350–400 | 380–440 | 410–470 | 440–520 | 470–550 | |

| HS800 | 210–265 | 280–330 | 300–350 | 330–380 | 360–410 | 380–430 | 410–470 | 440–500 | 470–550 | 500–580 | |

| HS900 | 260–335 | 325–385 | 345–405 | 375–435 | 405–465 | 435–495 | 455–515 | 485–545 | 515–585 | 545–615 |

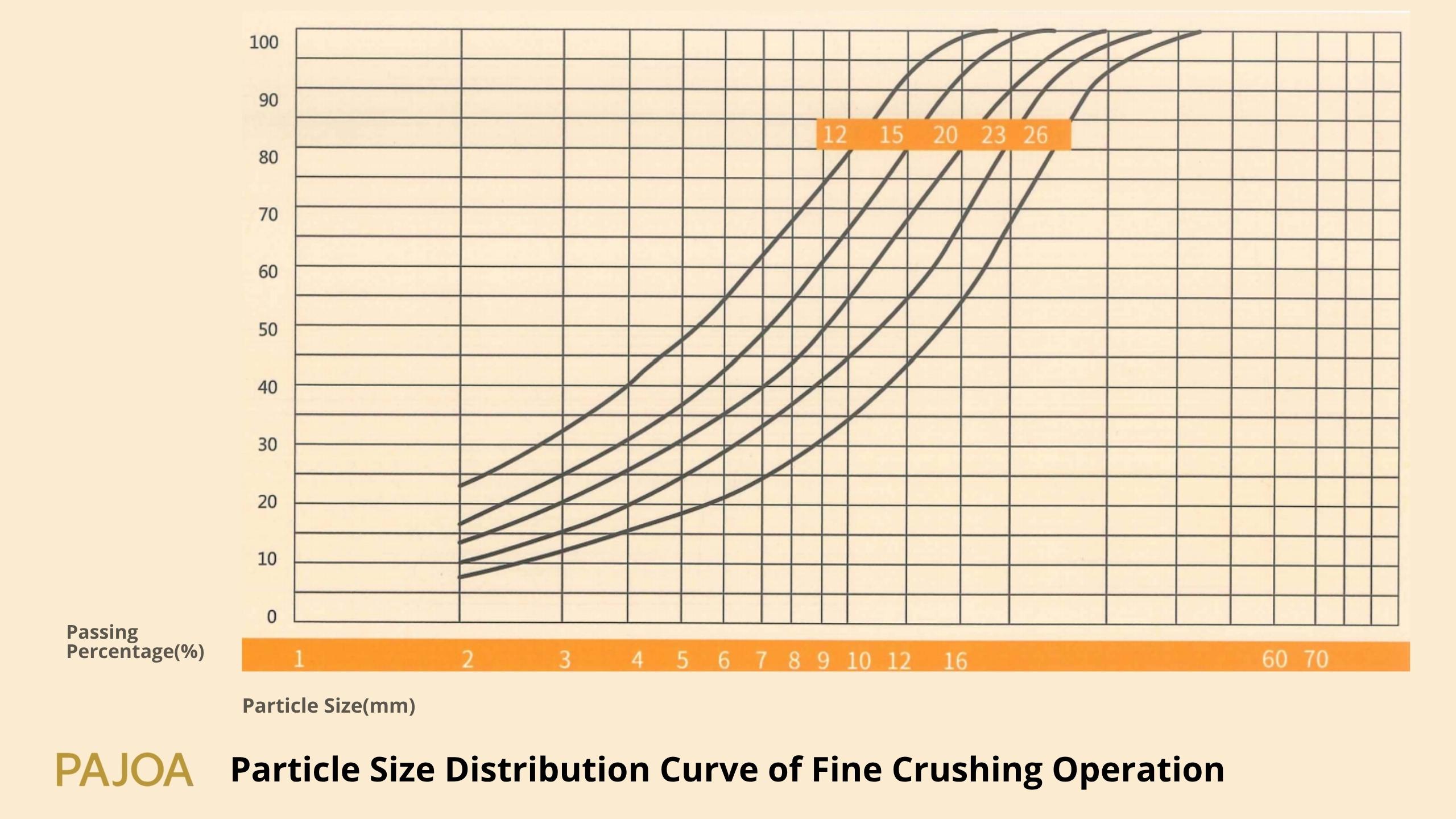

Chart 1: Fine Crushing Output Particle Size Distribution

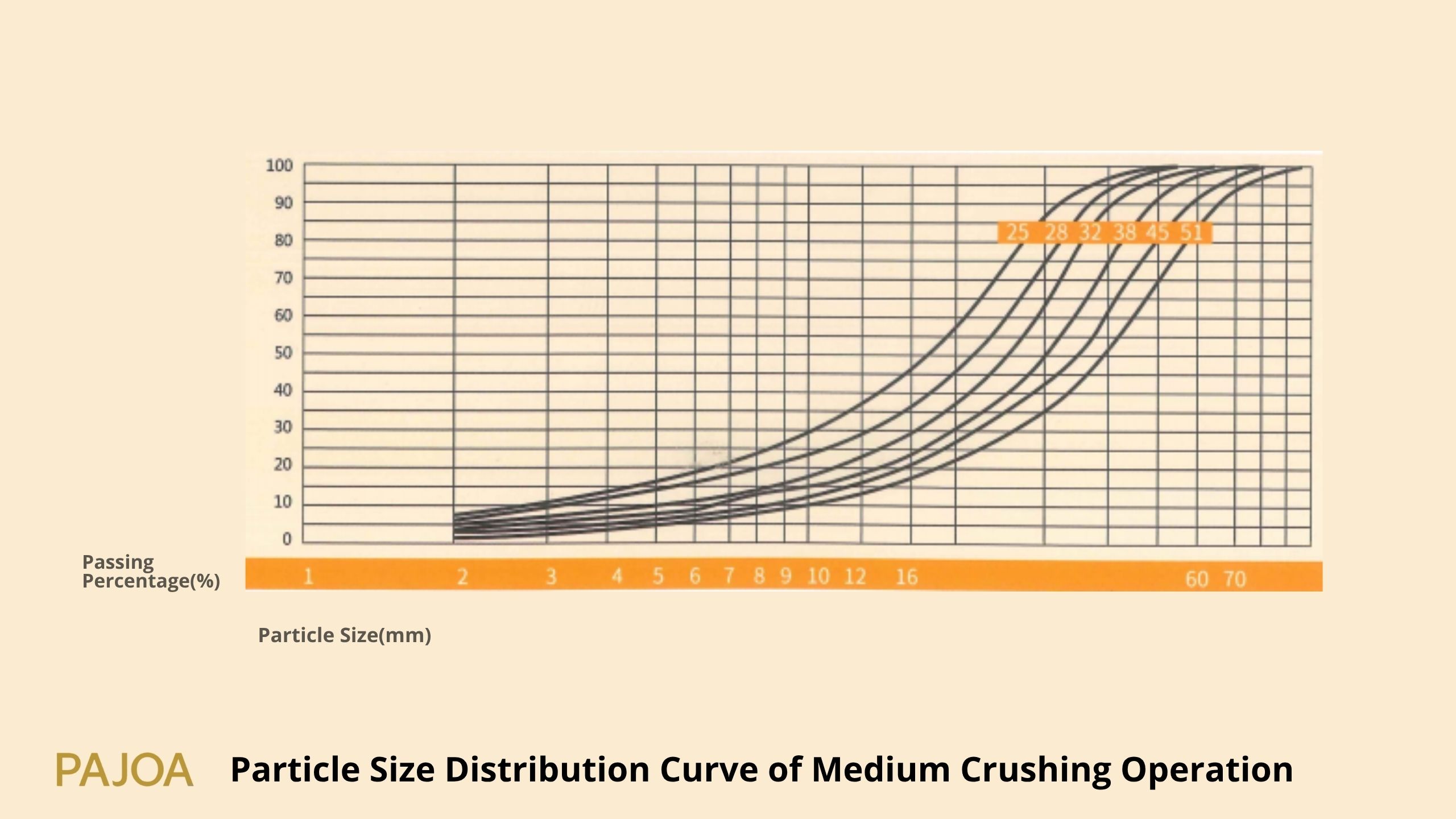

Chart 2: Medium Crushing Output Particle Size Distribution

The x-axis shows particle size in mm; the y-axis shows the percent passing (%), i.e., the proportion of material smaller than the given size.

The above particle size distribution curves illustrate the actual discharge gradation under different discharge opening settings.

The numbers shown (12 / 15 / 20 / 23 / 26, etc.) represent the crusher’s closed-side discharge settings (in mm).

Each curve indicates the percentage of final material that passes below a given particle size, under a specific discharge setting.

| Crusher Model | Cavity Type | Standard Type | Short Head Type | ||||

|---|---|---|---|---|---|---|---|

| Feed Opening A1 (mm) | Discharge Opening B2 (mm) | Min. Discharge C3 (mm) | Feed Opening A1 (mm) | Discharge Opening B2 (mm) | Min. Discharge C3 (mm) | ||

| HS200 | Fine | 95 | 128 | 14 | 25 | 66 | 6 |

| Medium | 125 | 156 | 16 | 54 | 70 | 6 | |

| Coarse | 185 | 208 | 19 | 73 | 114 | 10 | |

| HS300 | Fine | 107 | 148 | 13 | 25 | 72 | 6 |

| Medium | 150 | 190 | 16 | 53 | 100 | 8 | |

| Coarse | 211 | 240 | 17 | 123 | 140 | 9 | |

| Extra Coarse | 233 | 267 | 25 | – | – | – | |

| HS400 | Fine | 121 | 164 | 14 | 40 | 140 | 6 |

| Medium | 198 | 245 | 20 | 52 | 147 | 8 | |

| Coarse | 252 | 292 | 25 | – | – | – | |

| Extra Coarse | 299 | 333 | 30 | – | – | – | |

| HS500 | Fine | 133 | 180 | 13 | 45 | 135 | 6 |

| Medium | 204 | 246 | 20 | 49 | 105 | 7 | |

| Coarse | 286 | 322 | 25 | 66 | 130 | 10 | |

| Extra Coarse | 335 | 372 | 30 | – | – | – | |

| HS580 | Fine | 146 | 196 | 16 | 47 | 109 | 6 |

| Medium | 228 | 270 | 20 | 55 | 158 | 13 | |

| Coarse | 304 | 350 | 25 | 93 | – | – | |

| Extra Coarse | 330 | 375 | 30 | – | – | – | |

| HS800 | Fine | 219 | 250 | 5 | 33 | – | – |

| Medium | 297 | 332 | 12 | 155 | – | – | |

| Coarse | – | – | – | – | – | – | |

| HS900 | Fine | 211 | 269 | 18 | 101 | 124 | 8 |

| Medium | 259 | 317 | 27 | 156 | 151 | 9 | |

| Coarse | 286 | 342 | 30 | 172 | 170 | 10 | |

| Extra Coarse | 345 | 393 | 34 | – | – | – | |

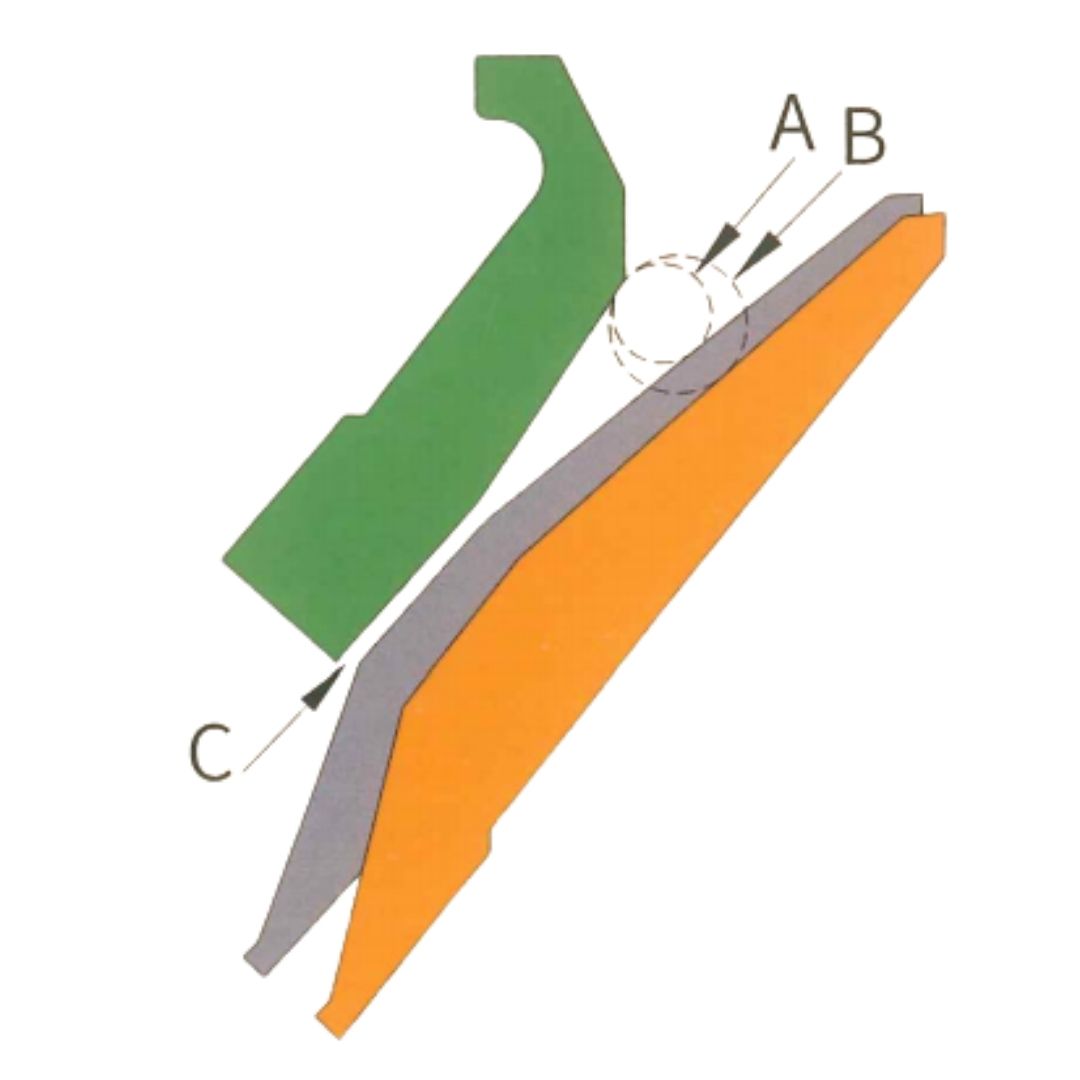

Примечание: A – Feed Opening (A1) B – Discharge Opening (B2) C – Minimum Discharge (C3)

| Модель | HS200 | HS300 | HS400 | HS500 | HS580 | HS800 | HS900 |

|---|---|---|---|---|---|---|---|

| Crusher Weight (kg) | 10,400 | 15,810 | 23,000 | 33,150 | 33,150 | 68,650 | 72,500 |

| Total Weight Incl. Motor, Oil Tank, Tools (kg) | 2,680 | 3,525 | 4,800 | 7,200 | 7,200 | 17,350 | 17,834 |

| Motor + Lubrication Pump Weight (kg) | 1,200 | 2,060 | 3,240 | 5,120 | 5,120 | 10,800 | 11,020 |

| Rated Motor Power (kW) | 132 | 200 | 315 | 400 | 400 | 630 | 710 |

| Transmission Shaft Speed (rpm) | 750–1,200 | 700–1,200 | 700–1,000 | 700–950 | 700–950 | 700–950 | 700–950 |

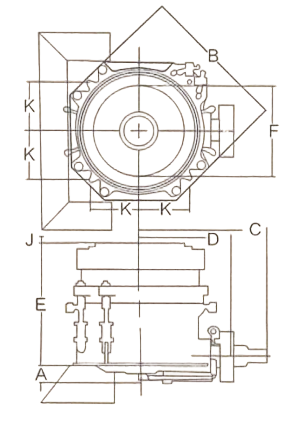

| Dimension Label | Описание | HS100 | HS200 | HS300 | HS400 | HS500 | HS580 | HS800 | HS900 |

|---|---|---|---|---|---|---|---|---|---|

| A | Oil Return Flange Height | 2,930 | 2,970 | 3,280 | 3,400 | 4,250 | 4,250 | 7,220 | – |

| B | Max. Diameter of Adjustment Ring | 1,505 | 1,952 | 2,207 | 2,370 | 2,465 | 2,730 | 3,070 | – |

| C | Distance from Feed Inlet Flange to Top | 1,560 | 1,900 | 2,010 | 2,070 | 2,170 | 2,450 | 2,870 | – |

| D | Crusher Base Height | 950 | 1,160 | 1,347 | 1,765 | 1,760 | 2,225 | 3,085 | – |

| E | Max. Discharge Height | 1,290 | 1,630 | 1,845 | 2,290 | 2,229 | 2,930 | 3,538 | – |

| F | Feed Hopper Inner Diameter | 690 | 914 | 1,078 | 1,360 | 1,335 | 1,863 | 3,030 | – |

| H | Distance from Discharge to Mounting Base | 1,725 | 2,140 | 2,580 | 3,130 | 3,165 | 4,305 | 5,890 | – |

| I | Distance from Discharge to Lubrication Pump Base | 1,700 | 2,165 | 2,455 | 3,165 | 3,165 | 4,530 | 6,160 | – |

| J | Distance from Motor to Feed Inlet Center | 65 | 75 | 85 | 105 | 115 | 125 | 150 | – |

| K | Feed Inlet Diameter | 435 | 546 | 680 | 826 | 890 | 1,020 | 1,200 | – |

| L | Discharge Outlet Inner Diameter | 970 | 1,240 | 1,470 | 1,740 | 2,040 | 2,420 | 2,620 | – |